Ifomu lokukhuphuka ngokuzenzakalelayo le-hydraulic i-LG-120, elihlanganisa ifomu lokukhuphuka ne-bracket, liyifomu lokukhuphuka elinamathiselwe odongeni, eliqhutshwa uhlelo lwalo lokuphakamisa i-hydraulic. Ngosizo lwayo, i-bracket eyinhloko kanye ne-climbing rail kungasebenza njengesethi ephelele noma ukukhuphuka ngokulandelana. Njengoba kulula ukuyisebenzisa nokuyiqaqa, uhlelo lungathuthukisa ukusebenza kahle kwakho futhi lufinyelele imiphumela yekhonkrithi efanelekile. Ekwakhiweni, uhlelo oluphelele lokukhuphuka ngokuzenzakalelayo lwe-hydraulic lukhuphuka kancane kancane ngaphandle kweminye imishini yokuphakamisa ngakho-ke kulula ukuluphatha. Ngaphandle kwalokho, inqubo yokukhuphuka iyashesha futhi iphephile. Uhlelo lokukhuphuka ngokuzenzakalelayo lwe-hydraulic luyisinqumo esingcono kakhulu sokwakhiwa kwezakhiwo eziphakeme kanye namabhuloho.

Esihlokweni sanamuhla, sizokwethula umkhiqizo wethu othengiswa kakhulu kusukela kulezi zici ezilandelayo:

•Izinzuzo zokwakha

•Isakhiwo se-Hydraulic Auto-Climbing Formwork System

•Ukuhamba Komsebenzi Wokukhuphuka kwe-LG-120

• Ukusetshenziswa kweIfomu Lokukhuphuka Ngokuzenzakalelayo Lomoya Obandayo we-Hydraulic LG-120

Izinzuzo Ekwakhiweni:

1) Ifomu lokukhuphuka ngokuzenzakalela le-Hydraulic lingakhuphuka njengesethi ephelele noma ngalinye. Inqubo yokukhuphuka izinzile.

2) Kulula ukuyiphatha, ukuphepha okuphezulu, futhi kuyabiza.

3) Uhlelo lokukhuphuka ngokuzenzakalelayo lwe-hydraulic uma seluhlanganisiwe ngeke luhlakazwe kuze kube yilapho ukwakhiwa sekuqediwe, okusindisa isikhala sendawo yokwakha.

4) Inqubo yokukhuphuka izinzile, ihambisana futhi iphephile.

5) Ihlinzeka ngamapulatifomu okusebenza aphelele. Abakhi akudingeki bamise amanye amapulatifomu okusebenza, ngaleyo ndlela bonge izindleko zezinto zokwakha kanye nomsebenzi.

6) Iphutha lokwakhiwa kwesakhiwo lincane. Njengoba umsebenzi wokulungisa ulula, iphutha lokwakha lingasuswa phansi ngephansi.

7) Isivinini sokukhuphuka kohlelo lwefomu siyashesha. Singasheshisa wonke umsebenzi wokwakha.

8) Ifomu lingakhuphuka lodwa futhi umsebenzi wokuhlanza ungenziwa endaweni ethile, ukuze ukusetshenziswa kwe-tower crane kuncishiswe kakhulu.

9) Ama-commutator aphezulu naphansi ayizingxenye ezibalulekile zokudluliselwa kwamandla phakathi kwe-bracket kanye ne-climbing rail. Ukushintsha indlela ye-commutator kungaveza ukukhuphuka okufanele kwe-bracket kanye ne-climbing rail. Uma ukhwela ileli, isilinda siyazilungisa ukuqinisekisa ukuvumelanisa kwe-bracket.

Isakhiwo se-Hydraulic Auto-Climbing Formwork System:

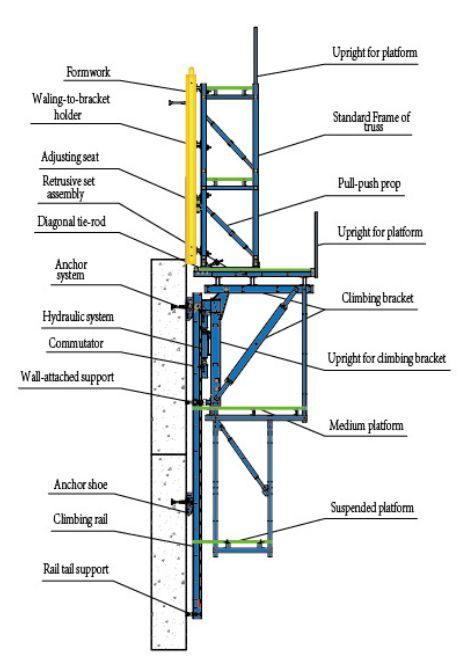

Uhlelo lwefomu lokukhuphuka ngokuzenzakalelayo lwe-hydraulic lwakhiwe uhlelo lwe-anchor, isitimela sokukhuphuka, uhlelo lokuphakamisa lwe-hydraulic kanye neplatifomu yokusebenza.

Ukuhamba Komsebenzi Wokukhuphuka kwe-LG-120

Ngemva kokuba ukhonkolo usuthelwe→Hlakaza ifomu bese ubuyela emuva→Faka amadivayisi anamathiselwe odongeni→Ukuphakamisa ireyili yokukhuphuka→Ukufaka i-bracket→Bopha i-rebar→Hlakaza bese uhlanza ifomu→Lungisa uhlelo lwe-anchor kufomu→Vala isikhunta→Ukhonkolo we-Cast

a. Ngokuphathelene nohlelo lwe-anchor olufakwe kusengaphambili, lungisa ikhoni yokukhuphuka efomini ngamabhawodi okufaka, sula ikhoni embobeni yekhoni ngebhotela bese uqinisa induku ye-tie enamandla aphezulu ukuqinisekisa ukuthi ayikwazi ukugeleza entanjeni yekhoni yokukhuphuka. Ipuleti le-anchor liboshwe ngakolunye uhlangothi lwenduku ye-tie enamandla aphezulu. Ikhoni yepuleti le-anchor ibhekene nefomu futhi ikhoni yokukhuphuka iphambene.

b.Uma kukhona ukungqubuzana phakathi kwengxenye ehlanganisiwe nebha yensimbi, ibha yensimbi kufanele isuswe kahle ngaphambi kokuba isikhunta sivalwe.

c.Ukuze uphakamise isitimela sokukhuphuka, sicela ulungise amadivayisi okubuyela emuva kuma-commutator aphezulu naphansi ukuze abe phezulu ngesikhathi esisodwa. Ingxenye engenhla yedivayisi yokubuyela emuva iphambene nesitimela sokukhuphuka.

d.Uma uphakamisa i-bracket, ama-commutator aphezulu naphansi alungiswa phansi ngesikhathi esifanayo, kanti ingxenye engezansi imelene ne-climbing rail (I-hydraulic console ye-climbing rail noma i-lifting rail isebenza ngumuntu okhethekile, futhi i-rack ngayinye ihlelwe ukuqapha ukuthi ivumelanisiwe yini. Uma ingavumelanisiwe, i-hydraulic valve control ingalungiswa. Ngaphambi kokuba i-bracket ikhuphuke, ibanga eliqondile phakathi kwamakholomu lingu-1m, kanti ibanga eliqondile lingu-1m. Ngemuva kwalokho, kusetshenziswa i-tape ebanzi engu-2cm ukuphawula, bese kufakwa izinga le-laser ukuze lijikeleze futhi likhiphe i-laser ukuze libone ngokushesha ukuthi uhlaka luvumelanisiwe yini).

Ngemva kokuba ireli yokukhuphuka isiphakanyisiwe endaweni yayo, idivayisi yokunamathisela odongeni kanye nekhoni yokukhuphuka yesendlalelo esingezansi kuyasuswa bese kusetshenziselwa ukushintshashintsha. Qaphela: Kuneziqoqo ezintathu zezinamathiselo zodonga kanye namakhoni okukhuphuka, amasethi ama-2 acindezelwe ngaphansi kwereli yokukhuphuka, kanti isethi eli-1 liyi-turnover.

Ukusetshenziswa kwe-Hydraulic Auto-Climbing Formwork System:

Isikhathi sokuthunyelwe: Jan-14-2022