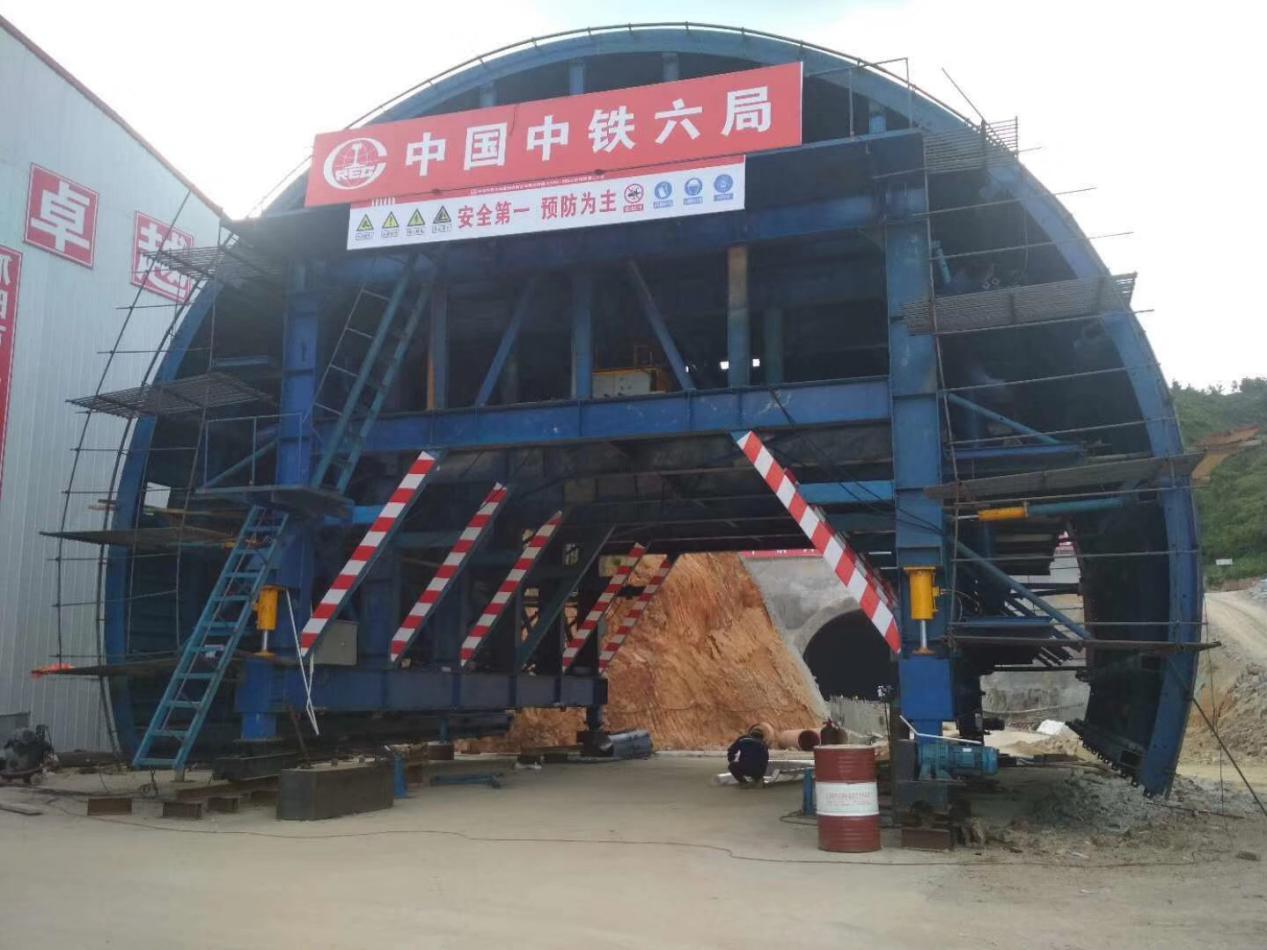

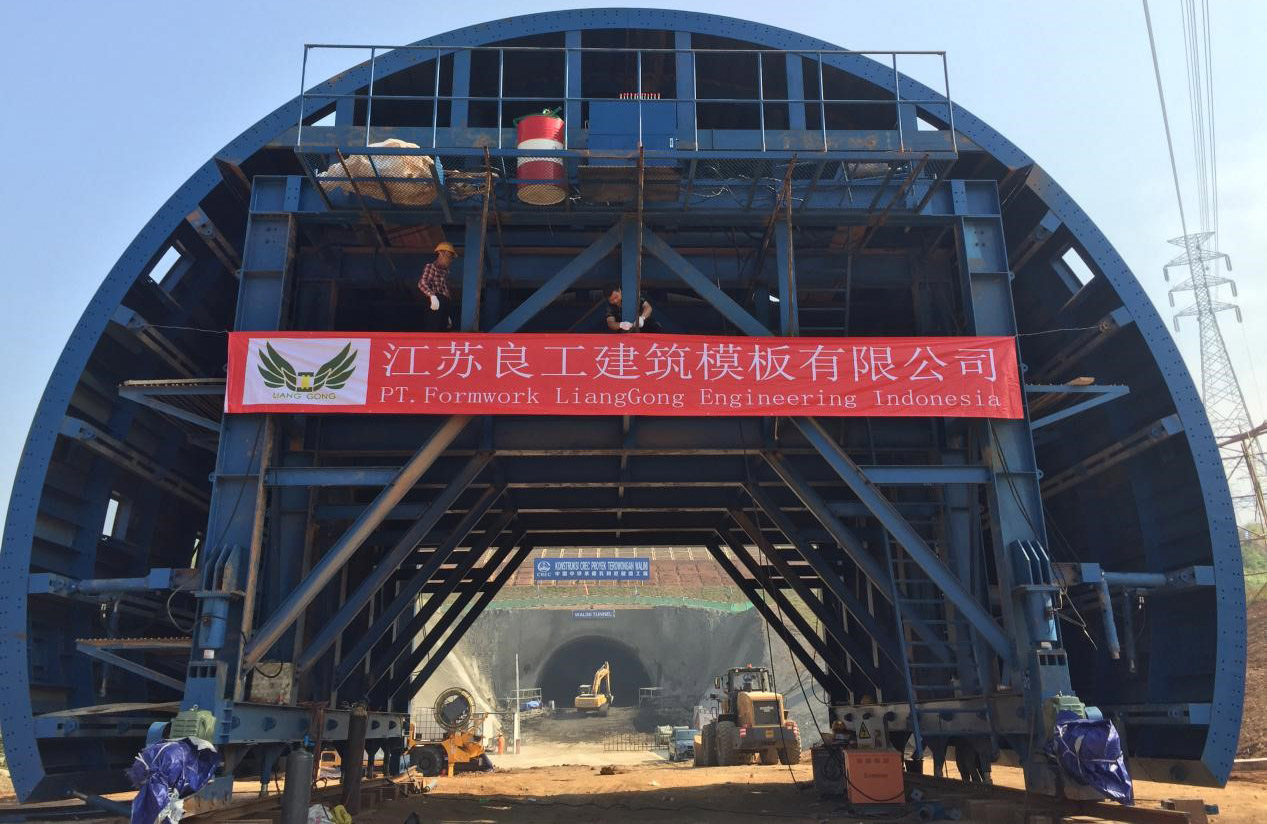

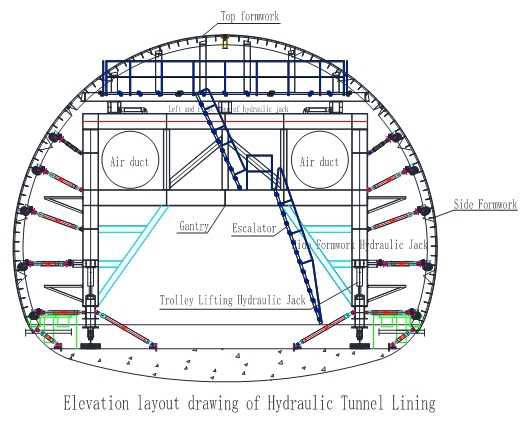

Iklanywe futhi yathuthukiswa yinkampani yethu, i-hydraulic tunnel lining trolley iyisistimu efanelekile yokwakheka kwemigqa yesitimela neyemigwaqo emikhulu. Iqhutshwa ngama-motor kagesi, iyakwazi ukuhamba nokuhamba yodwa, kanti i-hydraulic cylinder kanye ne-screw jack zisetshenziselwa ukubeka nokubuyisa i-formwork. I-trolley inezinzuzo eziningi ekusebenzeni, njengezindleko eziphansi, isakhiwo esithembekile, ukusebenza okulula, isivinini esisheshayo se-lining kanye nobuso obuhle be-tunnel.

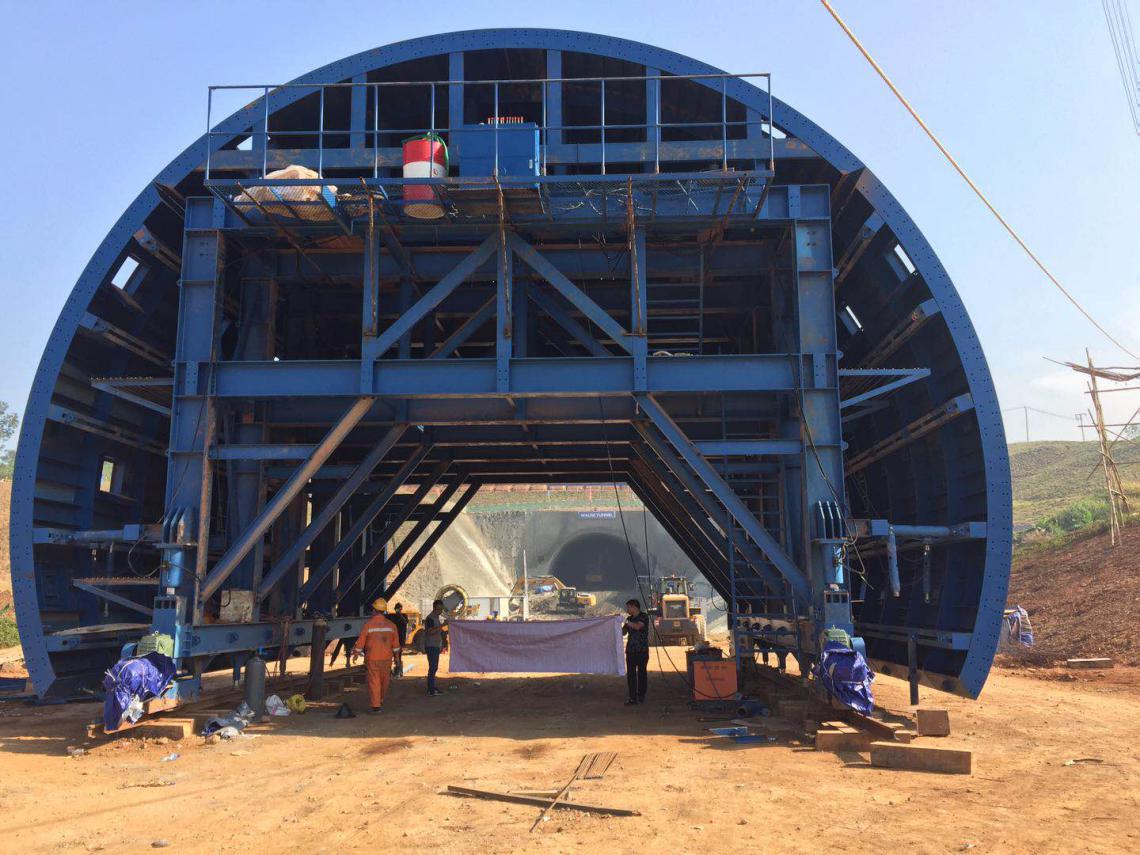

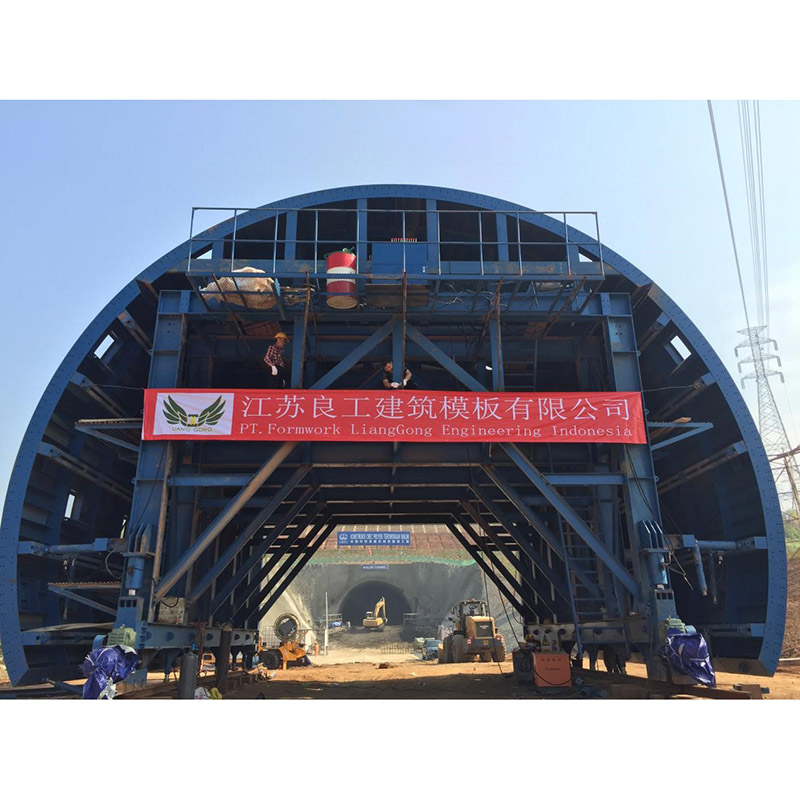

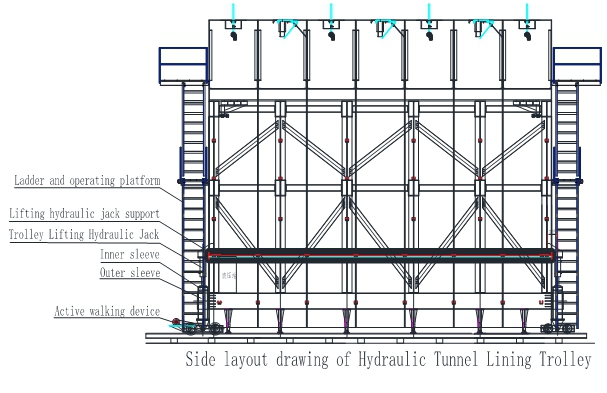

I-trolley ngokuvamile yakhelwe njengohlobo lwe-arch yensimbi, kusetshenziswa ithempulethi ejwayelekile yensimbi ehlanganisiwe, ngaphandle kokuhamba ngokuzenzakalela, kusetshenziswa amandla angaphandle ukuhudula, futhi ithempulethi yokuhlukanisa yonke isebenza ngesandla, okuyinto enzima kakhulu. Lolu hlobo lwe-lining trolley luvame ukusetshenziselwa ukwakhiwa kwemihubhe emifushane, ikakhulukazi ekwakhiweni kwe-lining yekhonkrithi yomhubhe ene-geometry eyinkimbinkimbi yendawo nendawo, ukuguqulwa kwenqubo okuvamile, kanye nezidingo zenqubo eziqinile. Izinzuzo zalo zisobala kakhulu. I-lining yekhonkrithi eqinisiwe yomhubhe yesibili isebenzisa ukwakheka kohlaka lwe-arch olulula, oluxazulula lezi zinkinga kahle, futhi ngesikhathi esifanayo, izindleko zobunjiniyela ziphansi. Iningi lama-trolley alula lisebenzisa ukuthululwa kokhonkolo okwenziwe, kanti i-lining trolley elula igcwele amaloli epompo ahambisa ukhonkolo, ngakho-ke ukuqina kwe-trolley kufanele kuqiniswe kakhulu. Amanye ama-lining trolley alula nawo asebenzisa i-integrated Steel Formwork, kodwa asasebenzisa izinduku ezinezintambo futhi awahambi ngokuzenzakalelayo. Lolu hlobo lwe-trolley luvame ukugcwaliswa ngamaloli epompo yokulethwa kokhonkolo. Ama-lining trolley alula ngokuvamile asebenzisa i-formwork yensimbi ehlanganisiwe. I-formwork yensimbi ehlanganisiwe ngokuvamile yenziwe ngamapuleti amancane.

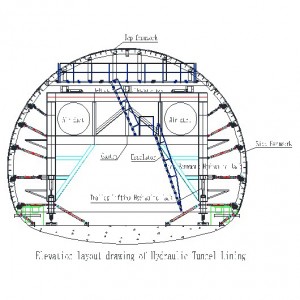

Ukuqina kwesakhiwo sensimbi kufanele kucatshangelwe enkambisweni yokuklama, ngakho-ke isikhala phakathi kwama-arches ensimbi akufanele sibe sikhulu kakhulu. Uma ubude besakhiwo sensimbi bungu-1.5m, isikhala esimaphakathi phakathi kwama-arches ensimbi akufanele sibe ngaphezu kuka-0.75m, futhi i-longitudinal joint yesakhiwo sensimbi kufanele ibekwe phakathi kokusunduza kanye nokusunduza ukuze kube lula ukufakwa kwezikhonkwane zesakhiwo kanye nama-formwork hook. Uma iphampu isetshenziselwa ukusunduza, isivinini sokusunduza akufanele sibe sishesha kakhulu, ngaphandle kwalokho sizobangela ukuguqulwa kwesakhiwo sensimbi esihlanganisiwe, ikakhulukazi lapho ubukhulu be-lining bungaphezu kuka-500mm, isivinini sokusunduza kufanele sehliswe. Qaphela lapho uvala futhi uthulula. Naka ukuthulula ukhonkolo ngaso sonke isikhathi ukuze uvimbele ukuthulula ukhonkolo ngemva kokugcwaliswa, ngaphandle kwalokho kuzobangela ukuqhuma kwesikhunta noma ukuguqulwa kwetroli.